Secure Conformal Coating for Your PCB Assemblies

As electronics become more integrated into everyday products, protecting sensitive components from environmental factors has never been more critical. At Odyssey Electronics, we offer advanced conformal coating and potting services to shield printed circuit boards (PCBs) from moisture, dust, chemicals, and extreme temperatures. Whether it's industrial electronics exposed to harsh conditions or medical devices requiring hours of operating time, we provide tailored solutions that protect your product and extend its lifespan.

With over 30 years of experience, Odyssey Electronics takes pride in delivering 100% US-based PCB assembly services, offering turnkey solutions tailored to your needs. From design and surface mount technology (SMT) to the final coating processes, we manage every aspect of your project in-house. Our commitment to quality assurance and precision at every stage allows us to manufacture circuit boards that meet the highest standards, providing peace of mind for engineers and product buyers alike.

What is Conformal Coating, & How Does It Protect Your PCB?

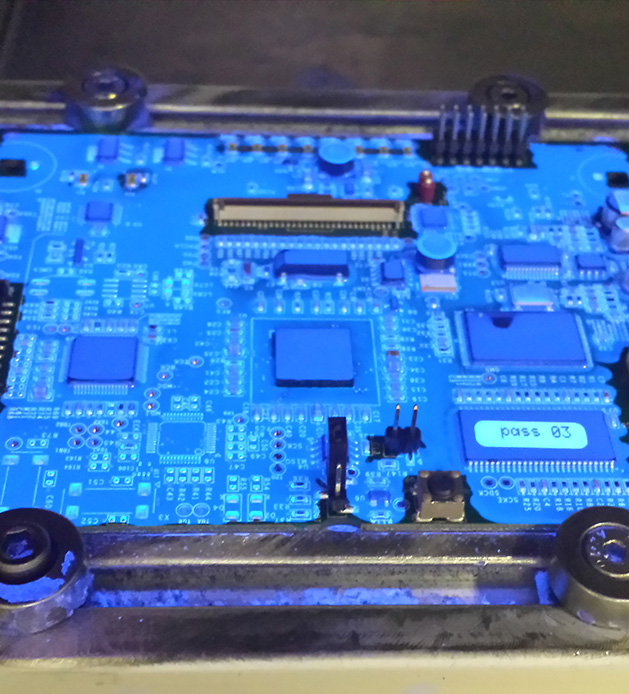

Conformal coating involves applying a thin, protective layer over your PCB to guard it against environmental stressors like moisture, chemicals, and dust. This coating is critical for electronics that operate in harsh conditions, such as industrial equipment, military systems, and outdoor technologies.

At Odyssey Electronics, we use state-of-the-art equipment to apply conformal coatings with precision, allowing your PCBs to maintain functionality and durability. For more robust protection, we offer potting services, where the entire assembly is encased in a protective material, further safeguarding your devices.

Partner with the Conformal Coating Experts at Odyssey

Our experience in PCB assembly spans over three decades, giving us the expertise to meet the needs of engineers and product buyers alike. Beyond conformal coating, we offer advanced technologies like surface mount technology, automated optical inspection, and turnkey solutions. With Odyssey, you're not just getting PCB assembly; you're partnering with a team committed to delivering trusted, high-quality results at every stage of production.

Advantages of Conformal Coating & Potting for PCB Assembly

Whether you need circuit boards to withstand moisture and salt on oil rig equipment or corrosive chemicals inside an industrial plant, our solutions can safeguard your devices. Conformal coating offers a protective barrier that shields your PCBs from elements like moisture, dust, and chemicals.

In situations where equipment faces extreme weather, like a satellite, potting adds even more protection by fully encasing components, making them highly resilient in any environment. Our technology keeps your electronics running smoothly, regardless of where they're deployed.

sales@odyssey-oei.com

sales@odyssey-oei.com