High-Quality PCB Assembly Services

The use of printed circuit boards (PCBs) continues to grow across industries as technology evolves and electronics become more complex. Each application brings different design requirements, manufacturing tolerances, and performance standards from consumer products to industrial systems. These variations call for more than just basic assembly—they require experience, attention to detail, and process control to meet the demands of each device.

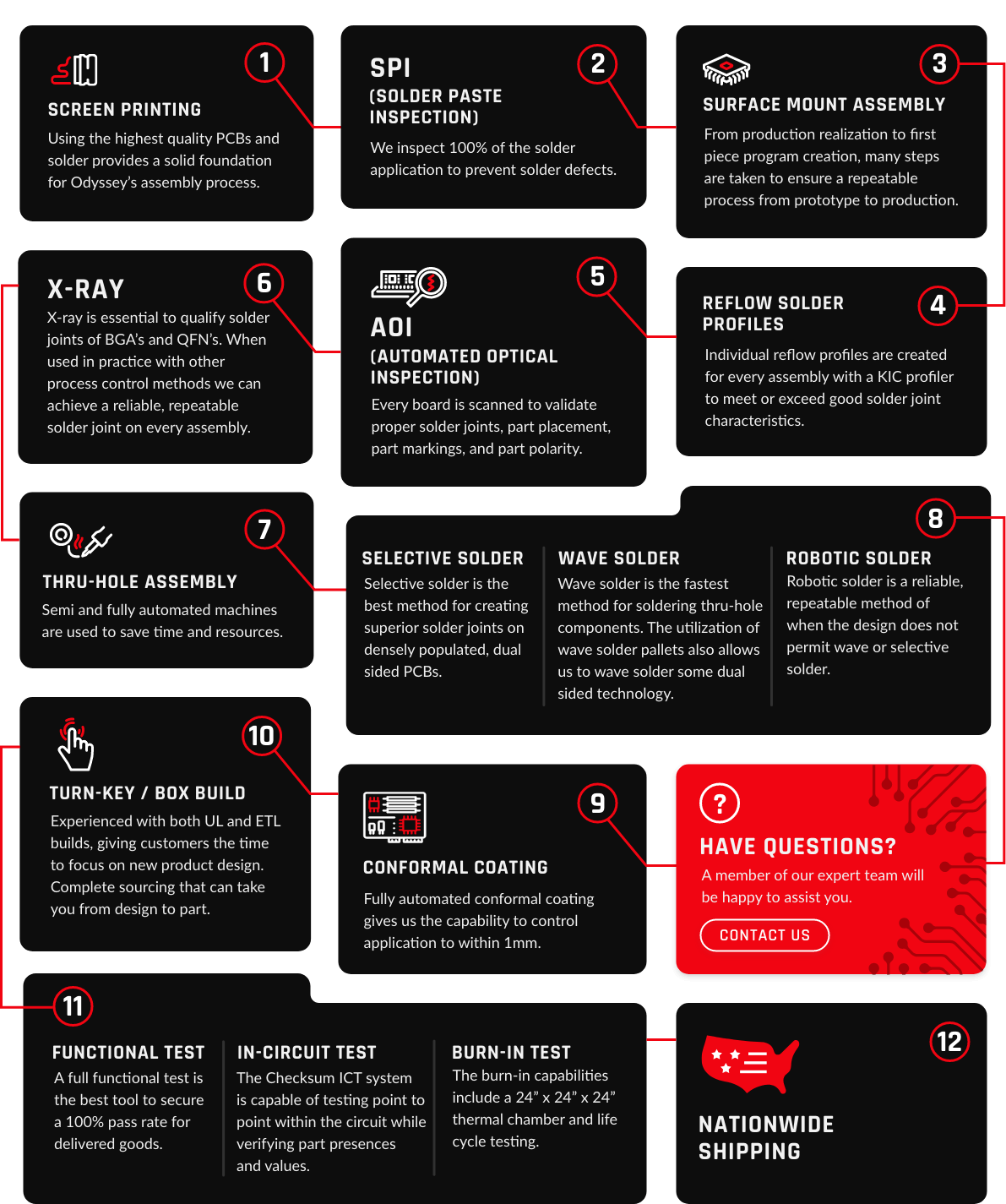

At Odyssey Electronics, we provide a comprehensive printed circuit board assembly service tailored to your application and industry. Our team brings decades of hands-on experience to every project, using proven methods and precision-driven workflows to ensure reliable results. Based in Livonia, MI, we provide our services to clients across America and Canada.

sales@odyssey-oei.com

sales@odyssey-oei.com